The Ocean Collect Project

- Home

- The Ocean Collect Project

10 TONS

of ocean waste collected so far.

We turn this →

into this

↓

The Background

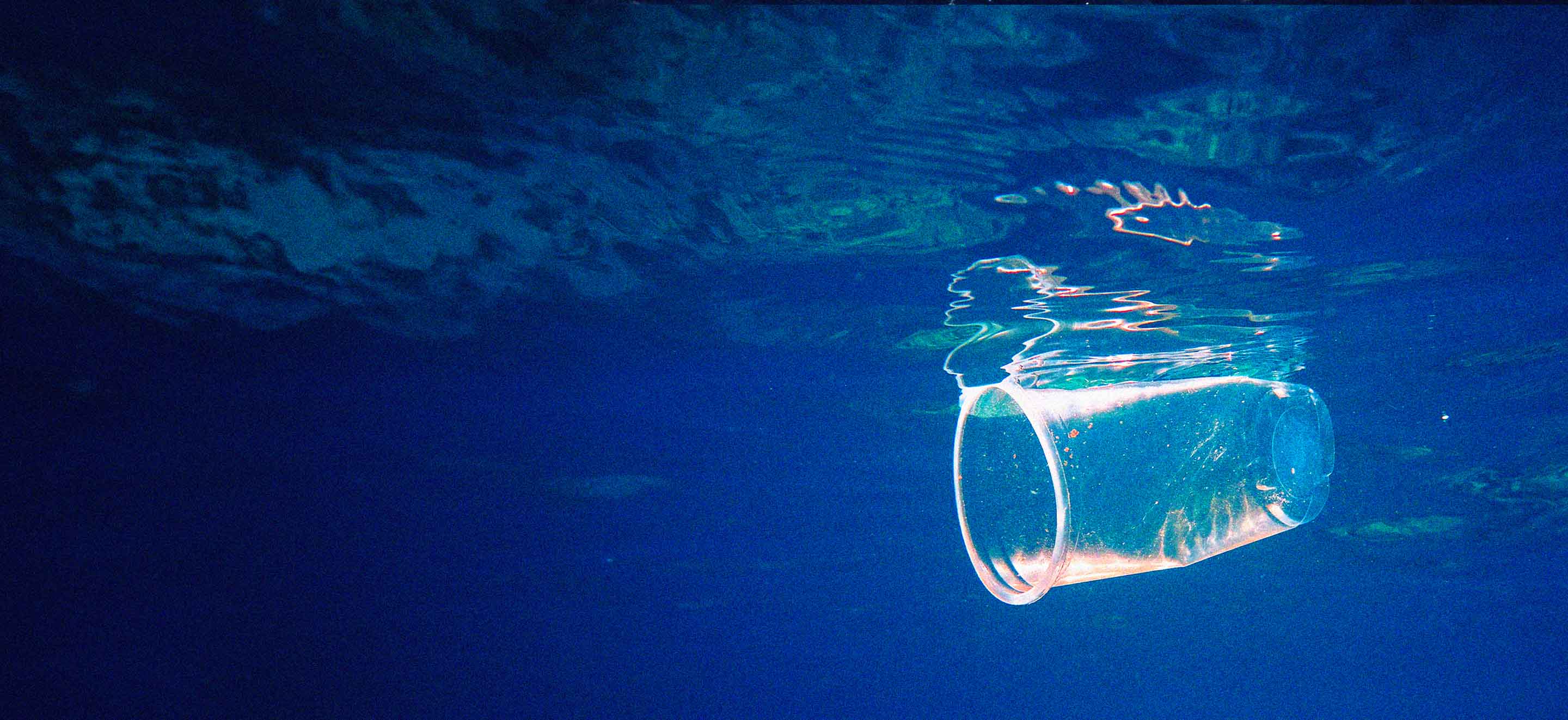

Every 15 years since the 1950s, the amount of plastic manufactured has doubled. This is the most rapid growth of any man-made material.

Ever.

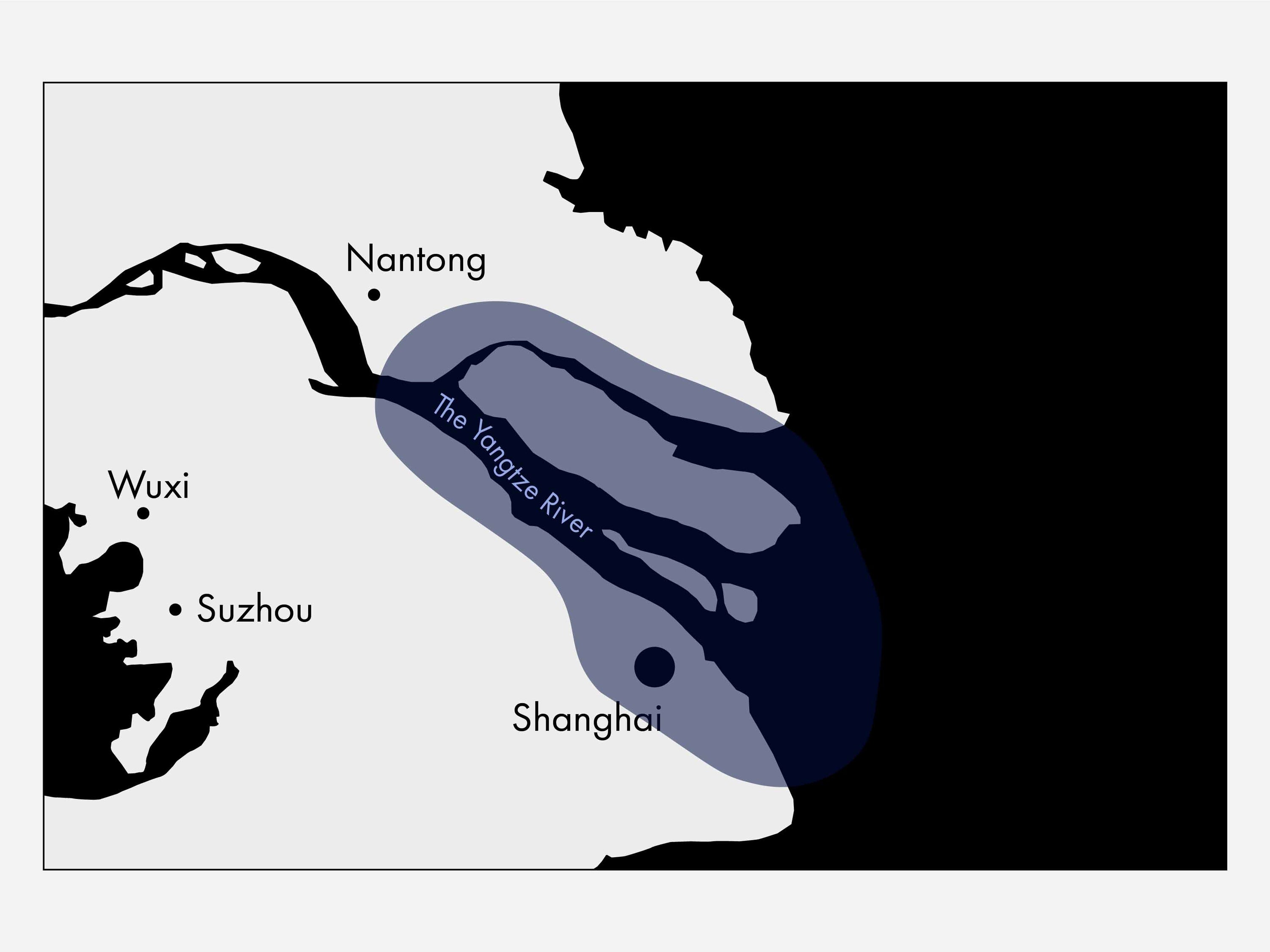

Only ten rivers contribute 90% of all plastic waste collected in the ocean.

Eight of these rivers are in Asia.

The Yangtze River is China's largest and the world's third-longest river. It sustains over 400 million people and is one of the world's most polluted rivers, responsible for 55% of the waste that ends up in the nearby seas and ocean due to a lack of efficient recycling infrastructure.

That's 1.5 millions tons per year.

We partner with our fabric supplier on their Ocean Fabric Initiative, combating ocean plastic pollution.

Besides removing plastic waste, we support waste pickers and former fishermen in polluted regions, boosting their income.

We also reinforce recycling systems in critical areas, like riverbanks and coastlines, to stop plastic from reaching the ocean.

Our bags are crafted from this collected waste.

The initial steps of the project

1. Identify

Plastic pollution hotspots along the Yangtze River and the East China Sea are identified.

2. Establish

A network of local collection stations is established. Training and equipment is supplied to increase efficiency and quality.

3. Collect

The plastic is collected.

4. Process

The plastic is processed, safeguarded by blockchain.

Blockchain Sequence:

MU5762-WE9365-JA2638-HY8573-WS7836-YN9784

From pollution, to solution...

A 6-step process.

Collection

A team of fishermen and volunteers embark on a mission to collect plastic waste from the Yangtze River and the East China Sea shorelines.

→

Sorting

The collected plastic is taken to a facility where machines sort it by type, colour, and origin for specialised processing.

→

Washing

The goal of this step is to remove impurities and everything that is not made from plastic.

→

Resizing

Resizing involves shredding plastic into small particles for easier processing and reshaping, also allowing a final check to remove any remaining non-plastic contaminants.

→

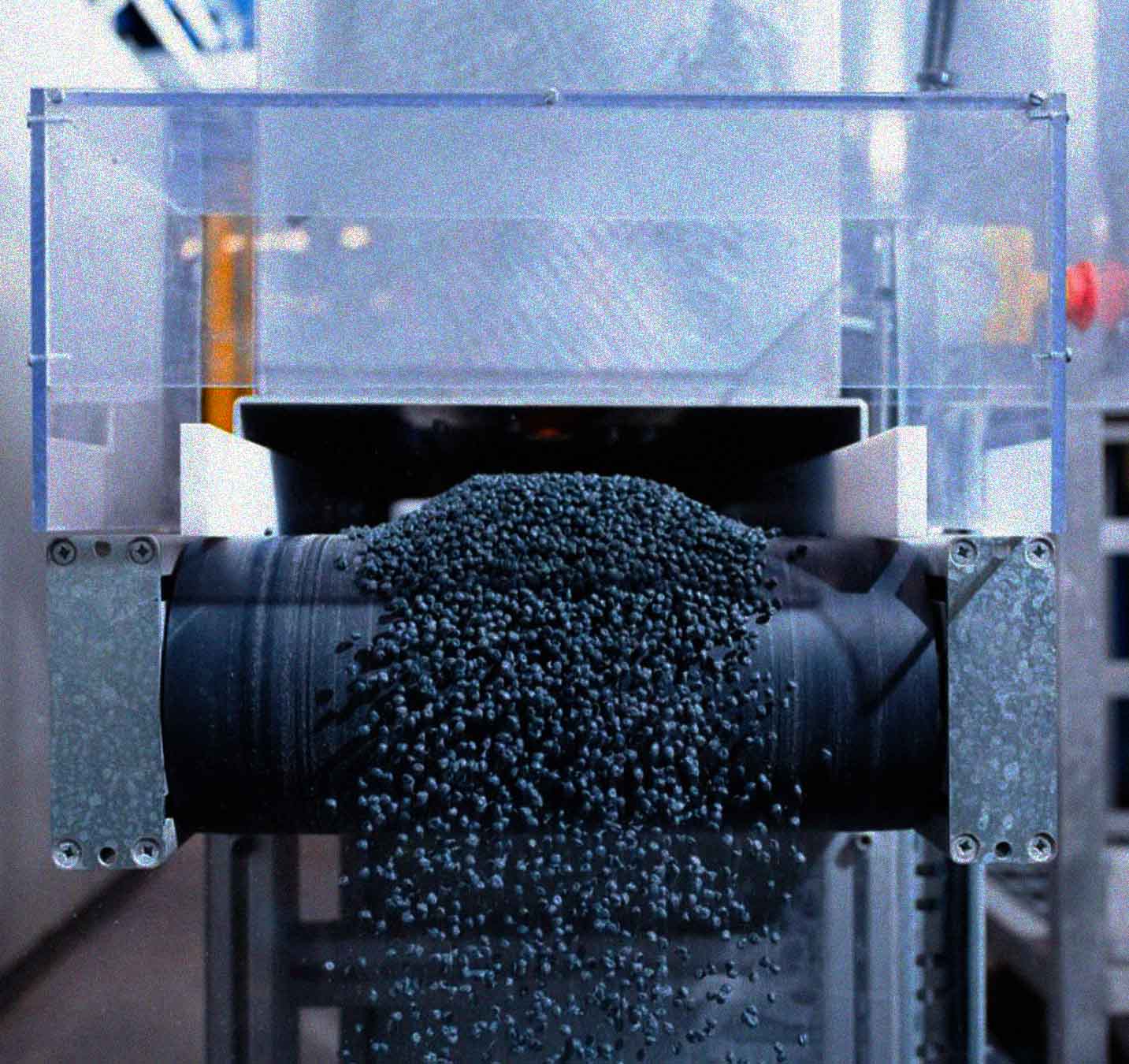

Compounding

Compounding is when the small particles are crushed and melted together into plastic pellets. The pellets can then be used in the production of our ocean waste fabric.

→

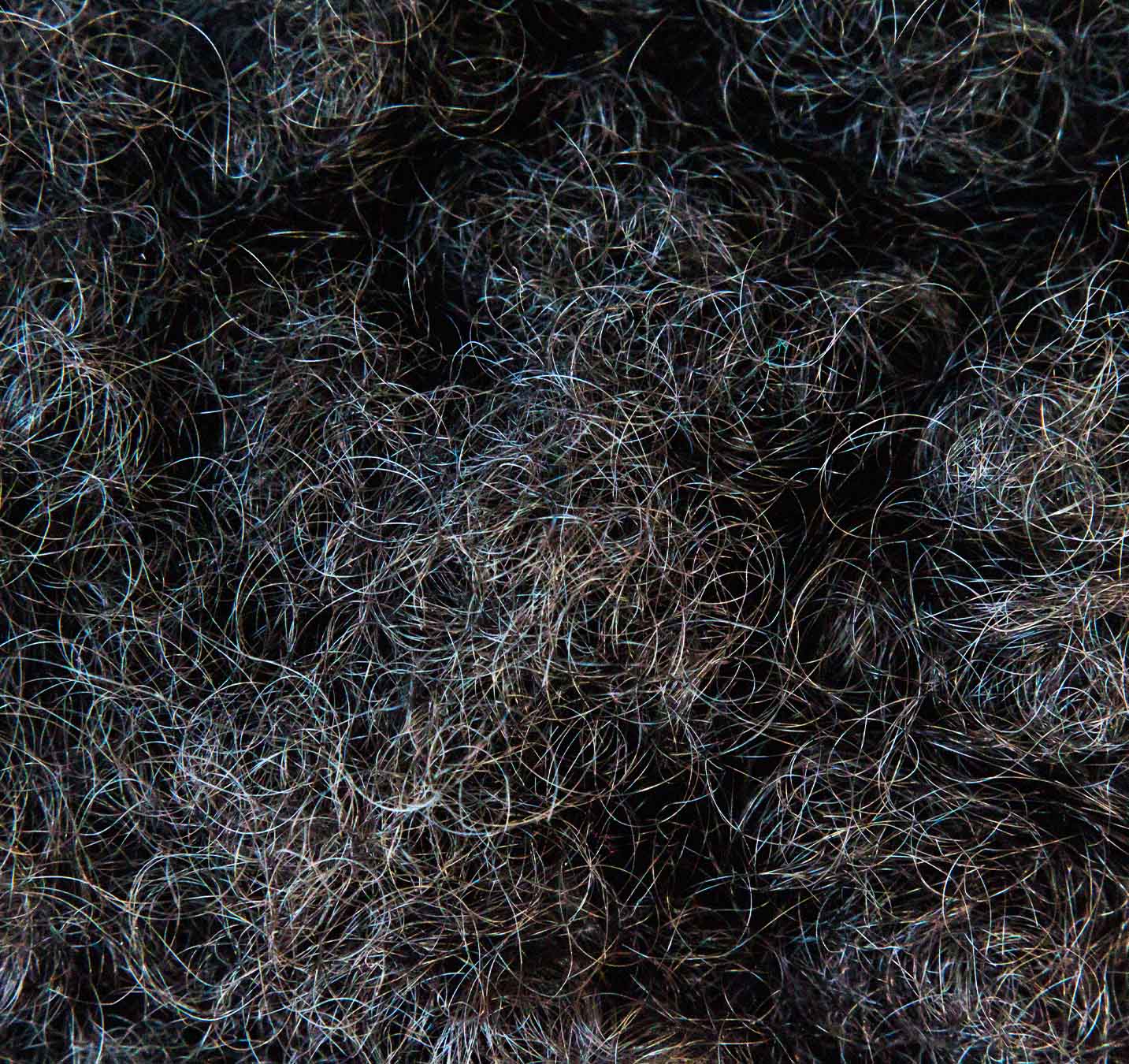

Yarn

The dry pellets are melted and pushed through tiny holes to form fine filaments, which are then cooled, tangled, and stretched to create a yarn ready to be woven into fabric.

-

Land & ocean plastics: durable fabrics

30% of our fabric is made from ocean plastic.

The other 70% comes from landfills, but there's a good reason for that.

The plastic waste we collect from the ocean, shorelines and river banks has often been breaking down for years, making it unstable. We add other stronger, recycled plastics to the mix to make sure our fabric is sturdy and durable.

By blending ocean and land-sourced plastics, we're able to create the most effective way of incorporating ocean plastics into our products while still keeping them affordable and high-quality.

The production of our ocean waste fabric uses:

86% less water

Than non-recycled fabrics.

75% less CO2

Than non-recycled fabrics.

70% less energy

Than non-recycled fabrics.